| Behavior of natural polycrystalline rocks | |||||

|

|||||

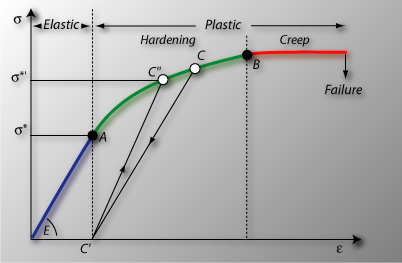

| Crystalline rocks display a behavior that incorporates the three elementary mechanical behaviors; rocks are elasto-visco-plastic material. The graph shows a characteristic flow curve for a polycrystalline material. At stresses below the yield stress, polycrystalline material behave elastically (blue curve). Above the yield stress, the material behave plastically. At low level of strain (green curve from A to B) the material becomes stronger as the applied stress must increases in order to keep the material deforming . At high level of strain (red line beyond B) the material flows under a constant stress. Under the hardening plastic regime, the removal of the driving stress leads to the removal of the elastic component of the deformation (curve CC'). If the sample is re-loaded with the same constant stress, elastic deformation occurs under an extended domain as the yield stress has increased (curve C'C''). This means that the material has become stronger.

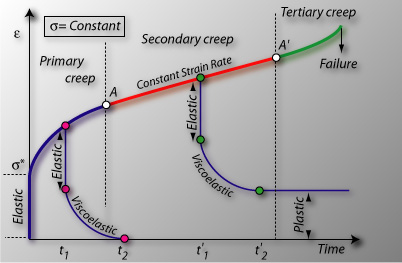

To understand how hardening occurs one must understand how strain is achieved at the microscopic scale. Plastic strain affects the arrangement of atoms and molecules in the lattice of rock forming minerals. During strain, this arrangement is perturbated by the introduction of defaults (gaps called dislocations). Each of them introduces a local elastic strain. Under stress, these defaults move around leading to permanent deformation. In the hardening plastic regime, the density of defaults increases but low stress levels impede their displacement, hence the elastic energy in the crystal lattice increases making the material stronger. The viscous behavior of polycrystalline material can be illustrated on a space strain versus time for experiment performed at constant stress. In this graph the flow curve can be divided into three plastic regimes called: Primary, Secondary and Tertiary creep. Primary creep corresponds to a reversible flow for which elastic deformation is instantaneously removed following unloading of the sample (at time t1), whereas another component of strain called viscoelastic deformation is also recovered but over of a time window t1 - t2. Secondary creep is characterised by a linear relationship between strain and time implying that the material is deformating at constant strain rate. Upon unloading elastic deformation is instantaneously recovered whereas the viscoelastic deformation is recovered over a period of time (t'1 - t'2). The sample, however, records a permanent plastic deformation. The tertiary creep corresponds to the development of a mechanical instability in which an increase in strain rate leads to the mechanical failure of the stressed sample. It is within the secondary creep regime that the rheological parameters that govern the rheology of rocks in the ductile regime are determined. |

|||||

|

|||||